Frequently Asked Questions

If your business is using lead-acid batteries or changing batteries in order to meet demands of a two or three shift operation, fast charging can help you save money and time. FastCharge Australia provides safe fast charging technology, that enables you to run your trucks on one battery all day with a quick charge during breaks and/or shift changes. This means you can eliminate the need for an entire battery changing operation, such as having battery rooms, changing batteries and having extra batteries. You can also increase productivity by eliminating time wasting trips to the battery room, along with extra maintenance on battery inventories. These savings can translate to as much as 40 percent over battery changing.

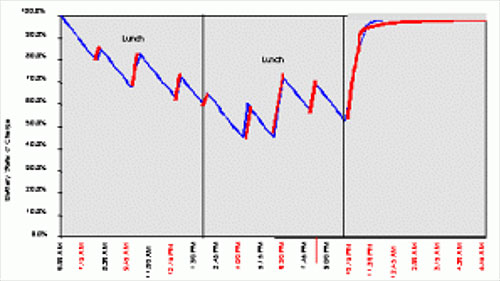

Fast Charging can take a 48-volt, 1000-amp hour battery from 20% state of charge to an 80% state of charge in approximately an hour with no cool down period required. That’s four times faster than a standard charger, but where fast charging is exceptional is during breaks and shift changes. By charging batteries correctly in your unit for 15 to 30 minutes at a time, you can keep your units performing strong between a 40% and 80% state of charge all day.

FastCharge Australia’s fast charging solutions are perfectly safe for batteries. It does not reduce the amp hour capacity of batteries any more than a conventional charger. Here’s how it works: batteries deliver a certain number of amp hours. Whether you use FastCharge chargers or standard chargers, you require the same amount of energy through your batteries. The difference is with Fast Charging you push the energy through the battery faster by pulling the required amp hours each day out of a single battery, Instead of pulling amp hours out of 2 different batteries. The result is a shorter life in terms of years, but not in actual amp hour throughput. Over the 15-year life of a charging system, standard chargers and fast chargers will use the same number of batteries.

Good news! DEKA East Penn, GNB, Crown Battery, Enersys, C&D, Hawker as well as many other battery companies have all issued fast charge battery warranties. These warranties, as well as warranties for retrofit of existing batteries may vary. For details, please contact one of our FastCharge representatives.

FastCharge Australia uses capable technology such as SBX or Euro connectors to connect the battery to the charger. Along with power, these connectors carry communications between the charger and our battery monitoring technologies such as our unique Battery Monitor and Identifier (BMID). The BMID constantly communicates battery temperature to the PowerStation where the vehicle is charging. The adaptive charging algorithm of fast charging constantly adjusts the charge rate, optimising its charge based on battery temperature and other parameters. It is the monitoring ability of the BMID coupled with the adaptive charging algorithm of the FastCharge station that prevents overheating in the battery. In addition to this, FastCharge Australia also have other fast charging systems monitor charging algorithms to also prevent overheating.

Cool down is required for conventional chargers for two reasons:

- Most conventional chargers must charge a battery at a standard temperature to be effective. A cooled down room temperature battery just provides a standard temperature. No cool down period is necessary for FastCharge solutions, as it constantly evaluates a battery’s temperature and adjusts the charger voltage accordingly.

- Recent tests conducted by major battery manufacturers have confirmed that, in contrast to popular belief, batteries can in fact operate at higher temperatures than previously thought, without loss of life or damage to the battery. However, battery temperature must be measured properly to charge and prevent overcharging and/or excessive gassing.

Opportunity charging commonly refers to the act of charging during breaks and shift changes with a conventional charger. FastCharge Australia’s solutions also charge during breaks and shift changes, but in addition, provides a completely different, safer, and more powerful charging method. The greatest differences boil down to two issues: 1) Fast charging pushes significantly more energy into the battery during quick charging, and 2) FastCharge solutions use a superior battery monitoring device to minimise heating by adjusting charging algorithms according to battery temperature. These devices also program the exact charging profile for the battery to prevent abusive overcharging typical of opportunity charging programs. Conventional chargers used for opportunity charging do not read battery state of charge, and therefore cannot prevent overcharging.

Yes, it is possible to save energy with FastCharge Australia’s products. Fast charging is more energy efficient because it charges to a maximum of 40-100% state of charge in contrast to standard chargers, which return between 108% and 115% of the amp hours removed. The extra “overcharge” represents energy wasted in gassing and heating. To estimate your savings, ask our representative to help you compare your usage and electricity costs with conventional chargers to a fast-charging system.

FastCharge Australia have learnt through years of experience, that one of the keys to a successful fast charge program is knowing exactly how and when people are using the system. Since any change is difficult to implement, FastCharge Australia have acquired software to track exactly who is charging, for how long and when. FastCharge also provides information much like an inline power prover. It reports beginning and ending voltage, current, and state of charge. It also records the cumulative amp hours in the battery. With this information you’ll know exactly when batteries require maintenance and replacement. In some cases, you can manage your charging program with fast charging, and reduce your fleet size. The data provided by our software systems can help any business evaluate fleet utilisation and reduction.

This data can be read from the charger’s digital display panel, or it can be downloaded to a PC for analysis and distribution.

FastCharge have universal battery chargers capable of charging nearly all common industrial batteries. This means if you have a fleet with various battery sizes and types, you only need one charger to power them all. Fast charging however, does require modification to the batteries so they can handle the high current charges.

DEKA, GNB, Crown Battery, C&D, Hawker, and Enersys all provide fast charge ready batteries. These new batteries differ from standard batteries in three ways. First, the cell-to-cell interconnects are made larger to handle high charging currents. Second, the battery connector is changed to accommodate the charger’s dual SBX or single Euro connections. And third, if required for maximum charge, most manufacturers can provide a special battery box that allows cooling air to flow through the battery pack.

You can retrofit your current standard batteries for fast charging by installing the above-mentioned interconnects and charger connections. The success of fast charging varies depending on your battery’s state of health. Our representatives will gladly evaluate this option with you.

The difference between our multi-vehicle MVS parallel charger and the “sequencer” type fast chargers is apparent in the way available charging power is delivered.

Let’s use the example of 4 trucks connecting simultaneously. With parallel charging, the system looks at the power requirements of each truck – this is determined by the size and voltage of the battery and its current state of charge – then prioritizes all the available power and distributes it accordingly. As a truck’s requirement diminishes, the power it was pulling is automatically shifted to other vehicles to get all trucks recharged as fast as possible. All the power available is being used to recharge vehicles.

In contrast, a sequential charger will prioritize trucks, and then it will send an 8-minute charge to each truck one at a time. This wastes valuable charging power, slows recharge time considerably, and heats batteries unnecessarily.

The greater efficiency of the PosiCharge MVS means you can have more charge ports per system and get the same or better results than with a sequencer. This translates to reduced equipment and installation costs. It also highlights the fact that evaluating a fast charger based on cost per port can be misleading. You aren’t just buying hardware with a fast charger – you’re buying charging ability.

Batteries create gassing when they become overheated and/or overcharged, or during equalisation, or at the end of a charge process. The FastCharge fast chargers prevent overheating by carefully controlling the charge algorithm according to the temperature in the battery, thereby control gassing. These advanced chargers also prevent overcharging by delivering a very precise charge, driven by the charging parameters programmed into the battery’s Battery Monitor or charger.

To minimise gassing effects during equalization, FastCharge fast chargers can be programmed to automatically equalize during weekends and overnight.

This chart shows a common 2-shift operation with two breaks and lunches and one shift change. As you can see, the truck’s state of charge stays between 40% and 100% throughout the day without ever making a battery change.

Nearly all accidents that occur during battery charging activities stem from a forklift transitioning to and from the battery room, a mishap with changing equipment, or battery acid spills. Since FastCharge fast chargers eliminate trips to the battery room, battery changing, and charging of extra batteries, it is a much safer charging method.

For added safety, the FastCharge systems verify the connection between the charger and the battery before starting a charge and monitor it at all times during charging. The connectors also have an instant disconnect pilot to prevent arcing if for any reason someone unplugs the battery in the middle of a fast charge. All fast charge systems and products meet industry standards and regulations.

FastCharge systems are completely automated. They are literally hands-free chargers: a driver pulls up, plugs in, and walks away. There are no settings to learn and no buttons to push, so the training required to teach a driver to fast charge a vehicle can be accomplished in minutes.

We're here to help

Let us help you reduce operating cost and maximise productivity for your operations. Call us on 1800 084 099 or enquire online.

Enquire TodayWhat our clients say

200+

Satisfied clients and companies that have proudly partnered with FastCharge Australia.

Need help?

Proudly based in Taree NSW, our team look forward to assisting you with your needs.

1800 084 099

PO BOX 9014, Taree West NSW 2430